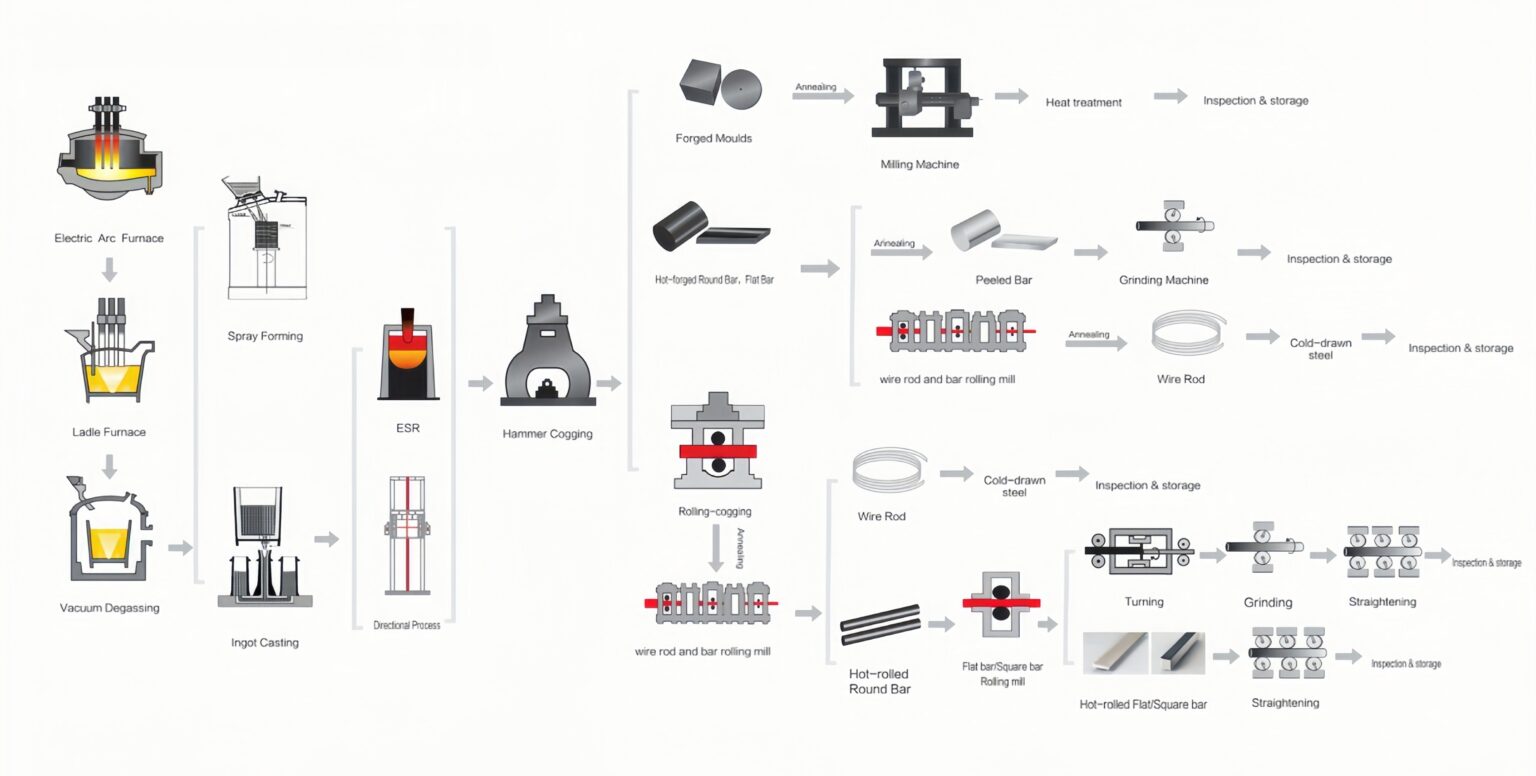

P30 high-speed steel is made using our self-developed directional process, which allows precise control of the steel structure. This process creates fine and evenly distributed carbides without segregation, avoiding the common problems found in traditional manufacturing methods. As a result, P30 offers stable and consistent performance.

Thanks to this advanced process, P30 high-speed steel provides higher hardness, better wear resistance, and stronger cutting performance than imported M35 and M42 high-speed steels, and can fully replace powder metallurgy steel ASP2030 in demanding applications.

| Execution standard | ZEICIN Grade | AISI | DIN | NACHI | Hitachi | Bohler | EARSTEEL | ASSAB |

| GB/T 9943-2008 | P30 | M36 | 1.3249 | FAX38 | HAP40 | S590 | ASP2030 | ASP30 |

| C | Si | S | P | Mn | Cr | Mo | V | W | Co |

| 1.23-1.33 | ≤0.70 | ≤0.025 | ≤0.025 | ≤0.40 | 3.80-4.50 | 4.70-5.30 | 2.70-3.20 | 5.90-6.70 | 8.00-8.80 |

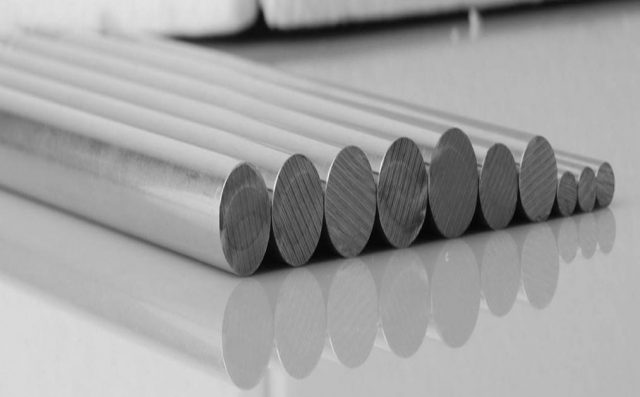

| Type | Specification(mm) | Surface condition |

| Hot-rolled Round Bar | Φ10.5-φ65 | Ground/Turned |

| Cold-drawn Steel Wire | Φ2.0-φ13.5 | Ground/Polished/Black |

| Band saw blade wire | 1.13*1.4 etc. | No decarbonization |

| Production | Material price | Workpiece | Rigidity of workpiece | Rotational speed | Lifespan |

| Screw Tap | P30 is 25%-30% of ASP2030 | 42CrMo Tempering test blank | 35.0~38.0 HRC | 110rpm | P30 as same as ASP2030 |

| Screw Tap | P30 is 25%-30% of ASP2030 | 42CrMo Tempering test blank | 35.0~38.0 HRC | 200rpm | P30 is 75% of ASP2030 |

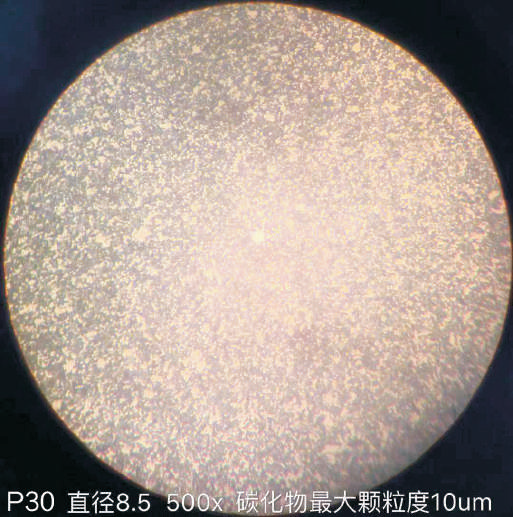

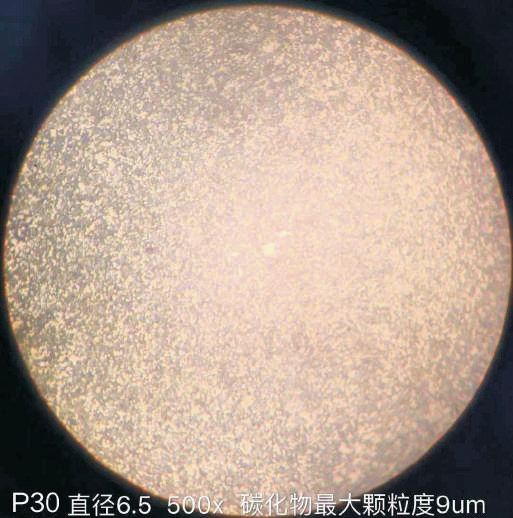

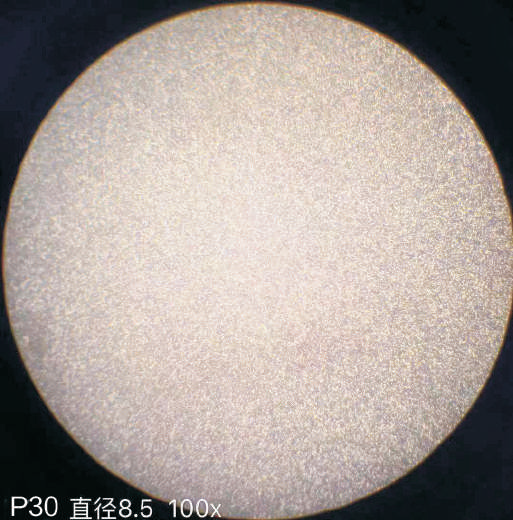

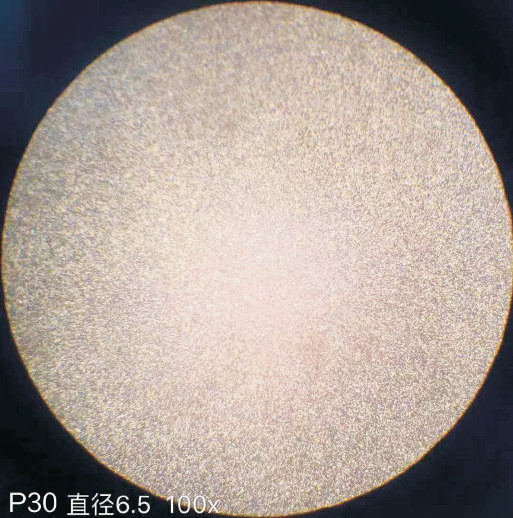

We use a unique Rapid Solidification Electroslag Remelting (RS-ESR) process to produce high-quality steel ingots. This process creates a fine and uniform carbide structure with a dense and compact microstructure. As a result, the steel shows strong grain boundary bonding, excellent wear resistance, high red hardness, and good toughness. Its overall performance is better than similar domestic materials and also superior to imported materials from Japan and Europe in terms of carbide size and distribution.

The RS-ESR process significantly reduces carbide grain size and minimizes the ledeburite carbide network, which helps lower material segregation and improve overall material quality.

This technology is independently developed by our company and is a unique process in China.

During RS-ESR processing, rapid cooling and fast solidification create a shallow molten pool. Carbides solidify quickly before they have time to grow, which keeps them small and evenly distributed.

By shortening carbide growth time, the process prevents the formation of coarse carbides and ensures a stable and high-quality microstructure.

P30 high-speed steel offers high hardness, strong wear resistance, and a stable microstructure, making it suitable for many types of cutting tools and industrial knives.

Common applications of P30 high-speed steel include:

Drills

Taps

Punches

Band saw blades

End mills

Tufting machine knives

Paper cutting knives

Under tough working conditions, P30 high-speed steel provides long tool life and stable performance. It is a reliable replacement for M35, M42, and ASP2030, and is widely used in high-performance tool manufacturing.

Q1: Do you accept trial orders?

A: Yes. We accept trial orders when the required size is in stock. This allows customers to test our product quality before placing bulk orders.

Q2: What is your delivery time?

A: If the products are in stock, delivery usually takes 5–7 days.

If the products are not in stock, delivery time is about 30–40 days, depending on the order quantity.

Q3: Do you offer discounts for bulk orders?

A: Yes. We offer discounts for bulk orders. The discount depends on the order volume and cooperation terms. Please contact us for detailed pricing.

Q4: How are the products packaged?

A: Our products use standard industrial packaging to ensure safe transportation. If you need custom packaging, please let us know when placing your order.

Q5: What payment methods do you support?

A: We support several payment methods, including T/T, L/C, Alipay, and PayPal. The payment method can be arranged based on the order amount and customer needs.